Top Hot-Dip Galvanizing Company in Malaysia

Free Consultation

Malaysia’s Leading Hot Dip Galvanized Steel Manufacturer

If you are looking for a top hot dip galvanizing company in Klang Valley, Malaysia, look no further than VG Steel Industries Sdn Bhd. We have been in business for over 10 years and have a proven track record of providing quality hot dip galvanizing services to our customers.

VG Steel Industries Sdn Bhd was incorporated in 2012 as a galvanized steel framing supplier in Malaysia, offering door, fence, roofing & banding products. Our strategically located plants in Shah Alam make it easy for our customers to access our hot dip galvanised services, and our annual capacity of 20,000 metric tonnes means we can meet the needs of even the most demanding customers.

We are one of the leading galvanized steel manufacturers in Malaysia, offering top-quality galvanized steel framing solutions in Malaysia and hot dip galvanised steel products.

Our Services

We are your trusted galvanizing company in Malaysia.

We offer a wide range of coating services, including anodizing services malaysia, electro-deposition (electrolyte), liquid, and powder coating for various structures. We also own the largest galvanizing kettle (by volume) in the world, which allows us to provide our clients with the highest-quality services and standards.

Our coatings services protect a wide range of products, enhancing their longevity, durability, and aesthetic appeal. Hot dip galvanized steel is treated with pure zinc oxide to make it more durable and less likely to rust. This process also protects the steel from corrosion and makes it sustainable. It also helps the product last for many years and be recyclable. Our hot dip galvanised services are one of a kind.

Your Reliable Hot-Dip Galvanizing Factory in Klang Valley, Selangor.

What is Hot-Dip Galvanizing?

Hot-dip galvanizing, also known as HDG, is a process in which steel is dipped in a bath of molten zinc. This coats the steel with a layer of zinc, which protects it from corrosion.

Hot dip galvanizing in Malaysia is one of the most widely used and effective methods of corrosion protection. The process can be used on both new and old steel and can be applied to various metals.

HDG is an environmentally friendly process that does not require harmful chemicals. The zinc coating also provides a sacrificial barrier, meaning that it will corrode before the steel does. This makes HDG an ideal choice for applications where corrosion protection is critical.

The Benefits of using Hot-Dip Galvanized Steel

There are many benefits as the following:

Cost-Effective

Hot-dip galvanizing is often viewed as a cost-effective method of protecting steel from corrosion. Compared to other coatings, it is the most economical choice in terms of both initial costs and long-term protection.

Total Immersion & Complete Protection

The hot-dip galvanizing process provides a complete protective layer for steel, from the innermost steel surface to the outermost. This is because steel is immersed in a bath of molten zinc during the galvanizing process. The uniformity of the zinc coating in Malaysia leaves no weak points for accelerated corrosion.

Maintenance-free

Once a galvanized coating has been applied, no further maintenance or upkeep is required. The long service life of hot dip galvanised steel means that it is virtually maintenance-free, which can save you time and money over the product’s lifetime.

Versatility

Galvanizing can be used in a wide range of industries to protect against corrosion. The cathodic protection from galvanizing is constant even in the toughest environment, making it a preferred choice for many.

Hardy, Durable

Galvanized coatings are tough and not easily damaged by abrasion during transport, erection, and throughout the steel’s service life. In addition, they can last for decades, providing a long-term solution to corrosion protection.

Why Should You Look for Hot Dip Galvanizing in Selangor?

Steel is protected from corrosion by hot dip galvanizing, which is also quick, affordable, and environmentally friendly. It also gives steel endurance and hardness. These are all solid justifications for galvanizing steel.

Longevity

Depending on the location, hot dip galvanizing typically offers a maintenance-free life of over 40 years. The coating ages relatively slowly, often gaining 1 to 1.5 microns nationwide every year. If repair is eventually required, elaborate preparation procedures are not needed, and the maintenance schedule is uncomplicated.

Application speed

The hot dip galvanizing process is quick. A full protective coating, including the steel’s preparation by acid pickling, can be applied in a matter of hours. An alternate paint technique, including drying time, may take longer than a week.

The toughness of the coating

Galvanised coatings are resistant to scraping and chipping, which can happen to painted metal and steel. In hot-dip galvanizing, the zinc is metallurgically joined to the steel and becomes a component of the building. Consequently, damage to hot-dip galvanized steel is far less likely to occur, especially during handling, storage, transit, and building.

Full Coverage

Thanks to hot dip galvanizing, all steel parts are coated, unlike painted systems. Zinc is applied inside and out, covering tricky edges and small gaps that are typically impossible to cover with any other method.

Ease in Inspection

Hot-dip galvanized steel is easy to inspect. An electronic probe can be used to swiftly verify the zinc thickness on the galvanized company’s product, which is stipulated by BS EN ISO 1461.

Speedy construction

If necessary, Construction can be completed more quickly if the steel has already been hot-dip galvanized. The benefit of not requiring “touch-ups” or any other procedures is that site times can be shortened.

VG STEEL INDUSTRIES SDN BHD is a committed galvanising steel company in Selangor striving to be a market leader in terms of quality, comprehensive customer service, and affordable costs. Modern production techniques and forward-thinking management guarantee growth and profitability to the delight of shareholders. With appropriate training and development in an exciting yet secure working environment, employees’ abilities and goals are recognized. With our honesty and fairness in all interactions with clients, regulatory bodies, and galvanized steel banding supplier in Malaysia, lasting relationships can be built.

Remember us when looking for hot dip galvanizing in Shah Alam, galvanized steel factory or a galvanized steel supplier in Malaysia.

Hot Dipped Galvanizing Applications in Malaysia

Galvanized steel is widely used in applications where rust resistance is needed. Hot-dip galvanizing is commonly used in various industries such as automotive, electrical, and construction.

Automotive Industry

The automotive industry is one of the main industries that utilize hot-dip galvanizing. Car bumpers, engine compartments, chassis, and other metal parts are commonly hot-dip galvanized to protect them from corrosion.

Highway Guardrails

Another sector that uses Highway guardrails is the electrical industry. As a trusted W-beam guardrail supplier, we typically make use of steel and then hot-dip galvanized to provide additional protection against corrosion. Because they are subject to a lot of wear and tear, they must be able to withstand the elements and remain strong over time. VG Steel is also a highway guardrail manufacturer providing top-quality highway guard rails for sale.

Construction Sector

The construction materials sector is also a major user of hot-dip galvanizing. Steel rebar, pipe, wire, and other construction materials are commonly hot-dip galvanized to protect them from corrosion.

Hot-dip galvanizing is also used in many other industries, such as shipbuilding, offshore oil & gas, petrochemicals, and many others. Some examples of applications used:

- Automotive parts

- Building materials

- Construction hardware

- Electrical components

- Pipe and tubing

- Storage tanks

- Structural steel

The main advantage of hot-dip galvanizing is that it provides long-term corrosion protection for steel products. In addition, it has excellent resistance to abrasion, impact, and chemical attack. As a result, hot-dip galvanizing is an ideal coating solution for Malaysia’s harsh climate and industrial environment.

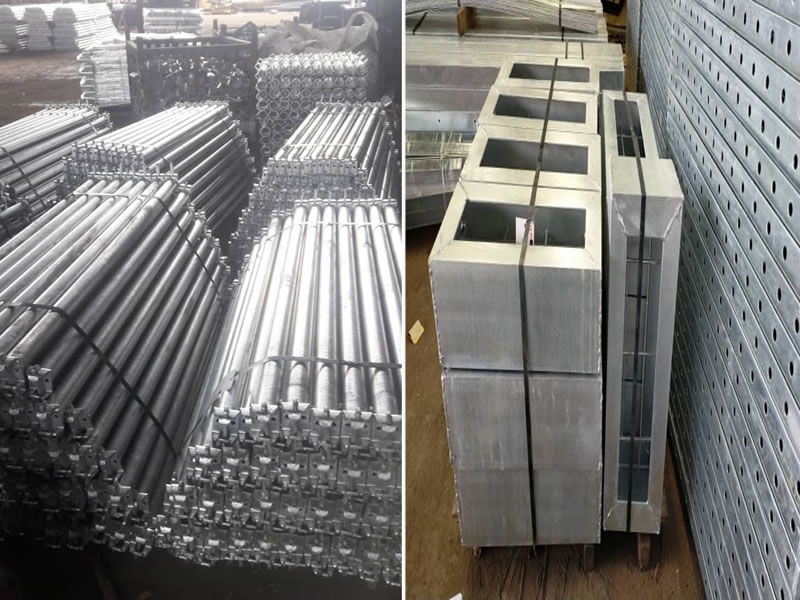

Our Hot Dipped Galvanizing Works

Frequently Asked Questions

Is hot-dip galvanized rustproof?

No, hot-dip galvanized steel is not rustproof. However, it provides excellent corrosion resistance for most environments.

How long does hot-dip galvanising last?

Dipped Galvanized coatings can last for decades, depending on the environment in which they are used. In harsher environments, the galvanized coating will corrode at a slower rate, prolonging the product’s lifespan.

How much does hot-dip galvanizing cost?

The cost of hot-dip galvanizing varies depending on several factors, such as the size and type of steel being coated. Contact us today for a free quote.

What’s the difference between hot-dip and cold galvanizing?

Hot-dip galvanizing involves dipping the steel product into a molten zinc bath while the cold galvanizing spray (coating) is applied using electroplating. Hot-dip galvanizing provides a thicker and more durable coating than cold galvanizing.

Contact Us Today

Contact VG Steel Industries Sdn Bhd today if you need hot-dip galvanizing services. With over 10 years of experience, we can provide high-quality hot-dip galvanized steel highway guard rails to meet your specific needs.